Service

Ultrasonic Inspection

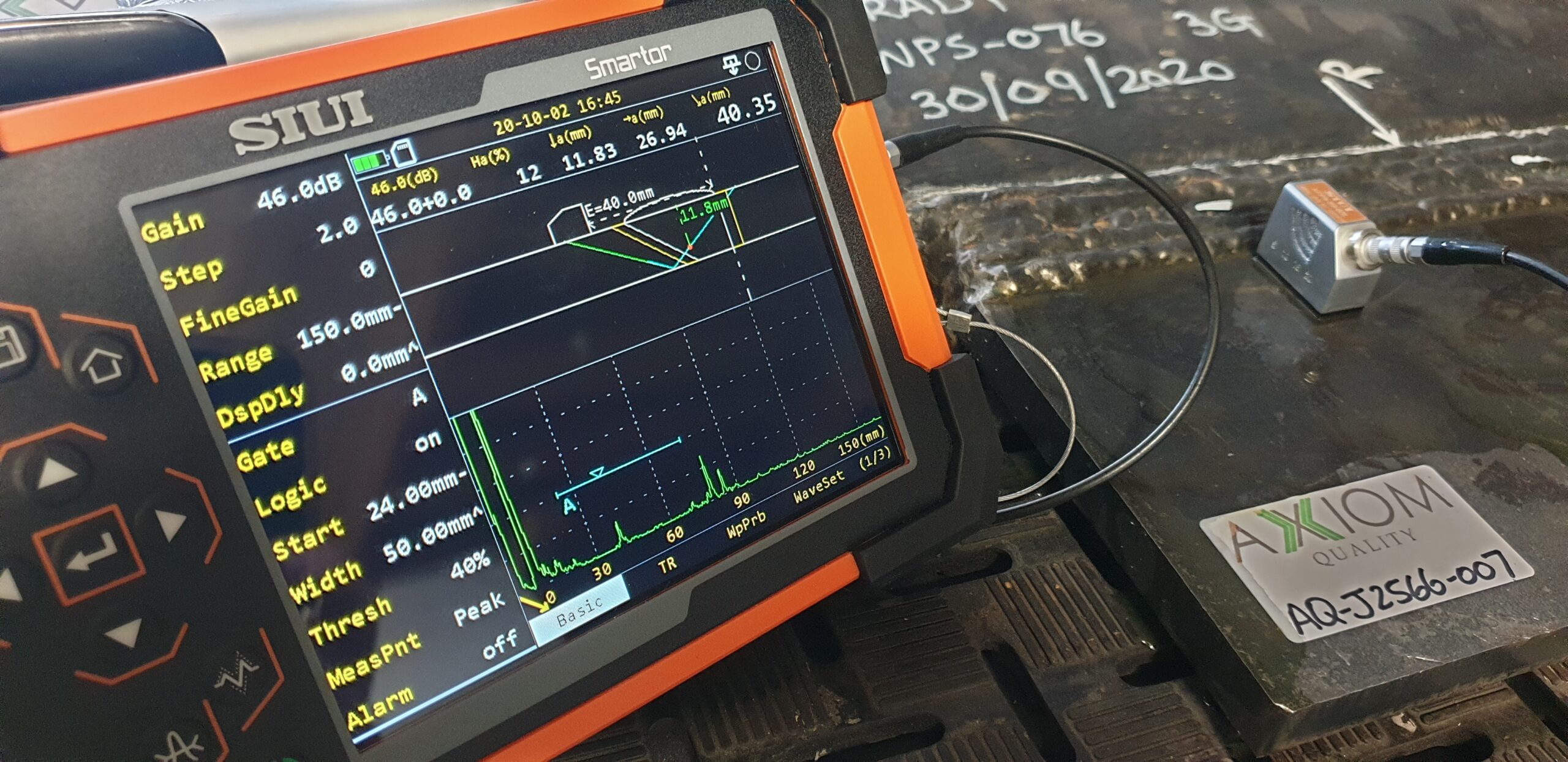

Ultrasonic (UT) is commonly used to determine sub-surface defects of welds and thickness of materials.

Flaw Detection and Thickness Survey available

Magnetic Particle Inspection

Magnetic Particle (MPI) is commonly used to determine surface defects of welds. Can only be used on Ferretic Steels. Both White Contrast and Black Light (Fluro) can be used.

Dye Penetrant Inspection

Dye Penetrant (DPI) is commonly used to determine surface defects of welds. Can only be used on any material to detect flaws

Professional and Precise NDT Testing

We offer a range of non-destructive testing to assess material, component, or structural properties to ascertain discrepancies and defective or discontinuous welding without damaging parts. Discover more about the NDT testing works we conduct.

Various Services That Fall Under NDT Testing in Perth

We provide ultrasonic inspection, commonly used to determine sub-surface defects of welds and the thickness of materials. We also offer flaw detection and thickness surveys.

If, instead, you require Magnetic Particle Inspection (MPI), commonly used to discover surface defects of welds, we can use this method on ferritic steels, where we use both white contrast and black light (Fluro).

We also provide Dye Penetrant Inspection (DPI) services which you can use on any material to determine the surface defects of welds.

Inspections & Testing You Can Trust

With our extensive experience, covering both inspection and testing activities. Our team of technicians is also qualified and has worked in the field, locally and globally, for several years. So, reach out to us for competent and reliable service.